Professional Manufacturer

Annual output of 160,000 tons.Annual turnover more than US100 million. Focus in phosphorous chemical produce since 2003.

Main Market

Our products are exported to many countries in Africa, Europe, Middle East, Southeast Asia, South America, etc...

Fast Delivery

Delivery time depends on the quantity and distance. What we can ensure is that we will arrange shipment very quickly.

About Chemate

For The Excellent Products And Service

With more than 15 years of production and export experience, our products and service have won high praise from our customers all over the world.

- Advanced Production Technology and Facilities

- Professional Technical and Sales Team

- Quality Assurance: ISO 9001, ISO14001 dual system certification.

- Competitive Price

- Excellent Service

Latest News

27MT Sodium Tripolyphosphate Ready to Be Shipped to Peru

Our company has an old customer from Peru. He has purchased chemical products from our company many times. Because he is very satisfied with our…

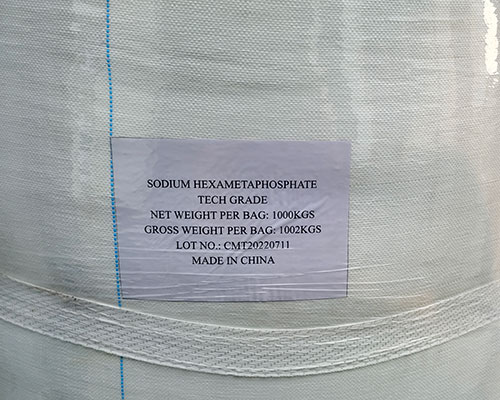

An Old Customer Ordered 100 tons SHMP

Congradulations on the successful delivery of 100 tons of SHMP powder ordered by our Saudi Arabian customer. This is the customer’s second purchase this year…

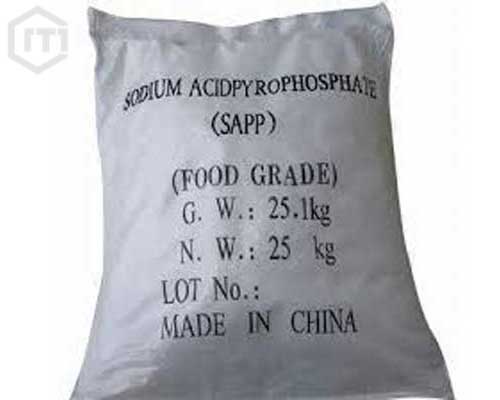

Is Sodium Acid Pyrophosphate Safe Used in Food

Sodium pyrophosphate or sodium acid pyrophosphate are edible phosphates, which are helpful for baking and fermentation, such as baking powder. It can help prevent food…